|

Hebei Anping County Jinhao Wire Mesh Co.,Ltd

|

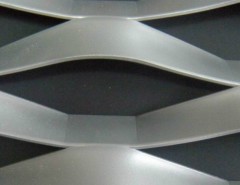

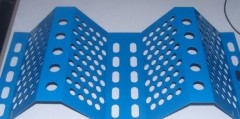

Rockfall netting,rockfall fence,wire mesh fence,iron rockfall netting,diamond hole,protection rockfall netting

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Rockfall netting

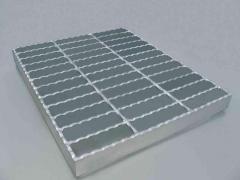

Materials and Feature: The mesh is made of heavily zinc coated or PVC Heavily Zinc coated double twisted steel woven wire. Due to the characteristics of double twist, this steel wire netting can with stand the force of falling rocks without unraveling in the event of wire breakage.

Steel wire used in the manufacture of the rock fall protection netting is heavily galvanized (zinc coated) mild steel wire. Rockfall protection netting with PVC coating can be used in aggressive environments. In addition to galvanization, the steel wire is coated with a PVC layer thickness of 0.50mm. The technical characteristics and the resistance of the PVC to aging meet the relevant standards.

Rockfall protection can be dealt with in two ways:

The one is curtain meshing the rock faces

By curtain meshing the face, spalling rocks can be either held in place by pinning the mesh to the rock strata or by draping it over the face guiding the falling rocks harmlessly to the base of the escarpment.

The mesh facing normally has vertical and/or horizontal cabling secured to the mesh/rock to provide fixity and integrity to the jointing of the panels. It is normal to seek advice from specialist installation companies as to the design of this type of work. Additional anchoring of large unstable rock masses on the face may be required.

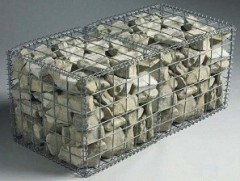

The other one is the catching walling

Catch walling rockfall protection is a freestanding gabion wall of sufficient mass to withstand impact of falling rocks. Location of the catch wall and height of the wall is important to ensure the trajectory of the falling rocks will be impacted on or behind the wall.

The one is curtain meshing the rock faces

By curtain meshing the face, spalling rocks can be either held in place by pinning the mesh to the rock strata or by draping it over the face guiding the falling rocks harmlessly to the base of the escarpment.

The mesh facing normally has vertical and/or horizontal cabling secured to the mesh/rock to provide fixity and integrity to the jointing of the panels. It is normal to seek advice from specialist installation companies as to the design of this type of work. Additional anchoring of large unstable rock masses on the face may be required.

The other one is the catching walling

Catch walling rockfall protection is a freestanding gabion wall of sufficient mass to withstand impact of falling rocks. Location of the catch wall and height of the wall is important to ensure the trajectory of the falling rocks will be impacted on or behind the wall.

Contact:Rachel Ren

Skype:rachelren2013

Company:Anping County Jinhao Wire Mesh Co.,Ltd

Related Search

Rockfall Netting

Wire Mesh Fence Netting

Protection Fence Netting

Iron Fence Netting

Mesh Fence Netting

Fence Netting Mesh

More>>

.gif)